State of the art facility.

Cold Chain Integrity is the largest certified full-service cold storage facility in the Tri-State, providing “best-in-class” cold chain management protocols, processes, and practices for the Food, Flavoring, and Pharmaceutical Industries.

Certifications & Accreditations

You’re in control, 24/7.

With e-Coldchain, you can track product, pallet, temperature, and shipping information anytime, from anywhere. Cold Chain Integrity utilizes IBM’s COGNOS Business Intelligence and Financial Performance Management Software. Through our web portal, customers access a secure, real-time, Internet-based information service. The e-COLDCHAIN portal is fully integrated with our SCE WMS providing customers with 24/7 visibility to virtually all aspects of their account.

In addition to the many canned or customized reports powered by COGNOS, CCI customers will be able to explore their account data in any combination and over any time period with a broad range of analytics capabilities. For those customers that have non-EDI, electronic commerce requirements, CCI can provide data per customer specs in PDF, XLM, TEXT or virtually any format.

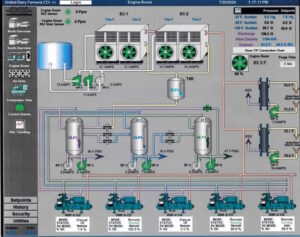

Computerized Refrigeration Control System

Cold Chain Integrity’s computerized refrigeration control system utilizes Frick software and controls that modularizes and standardizes the various control functions of our industrial refrigeration system. This state-of-the-art refrigeration control system utilizes an interconnected set of microcontrollers to optimize the management of various functions. Critical variables such as compressor sequencing, condenser head pressure control, vessel level and pump control, evaporator and defrost control, leak detection and alarm, kW monitoring and energy optimization are adjusted within established parameters allowing for the most efficient administration of the refrigeration systems. Our system makes critical variables – pressure, temperatures, infrared and current sensing – visible in real-time and collects historical control data for future reference.

RF (Radio Frequency) Bar Code Scanning

RF (Radio Frequency) Bar Code Scanning

Cold Chain Integrity has radio frequency handheld and forklift mounted tracking hardware in all of its warehouses to continuously update inventories and order status. Scanning enables us to capture and transfer data on a virtual real-time basis. Real-time, immediate access to product, pallet and shipment information ensures accurate movement of product in, out and within our warehouses. All this information is available to our customers through our online, customer support site, eCOLDCHAIN, providing visibility to inventory and shipment status

E-Commerce

E-Commerce

Cold Chain Integrity currently supports transactions with many trading partners. Order transmittals, shipment confirmation, updated inventory, quality holds and releases and order status transaction sets are currently supported. CCI will provide customer specific data transaction sets to meet their information needs.

Supply Chain Management & Warehouse Management System

Supply Chain Management & Warehouse Management System

Cold Chain Integrity utilizes Infor’s best-in-class SCE Warehouse Management System, which enables end-to-end fulfillment from order inception to order shipping, making it possible to fulfill the promise of the perfect order. CCI customers can access inventory information and events via their web browser for real time visibility of order status, shipments and inventory availability. Through secure access, customers can view and generate reports on orders, inventory, and transactional data across multiple locations to support planning and decision-making.

CCI continues to invest in supply chain systems upgrades and enhancements, including tools for event management. This can greatly reduce the need for safety inventory often required due to traditional information gaps, yet still assures exceptional order fill rates. CCI customers can then manage by exception, with notification via pager, fax, or email when go/no go parameters are triggered, such as order acknowledgments, back-order situations, order shipments or delays.